Redefining the Foundation: The Architecture of Efficiency

The Shift to High-Voltage and Unified Structures

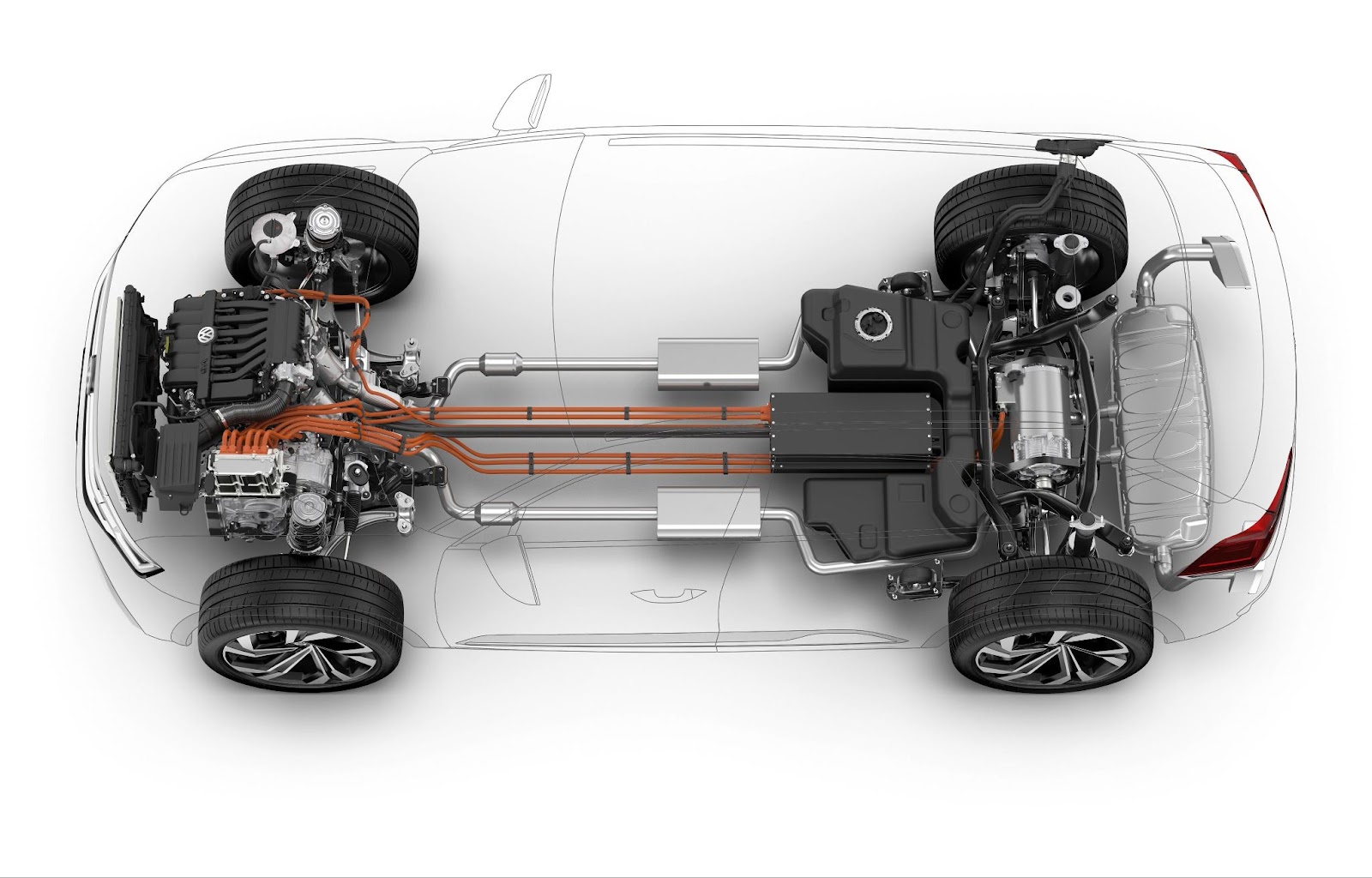

The philosophy behind vehicle construction is undergoing a radical departure from traditional automotive engineering. We are moving away from the era where electric components were simply retrofitted into combustion-engine chassis. Instead, the industry is embracing a holistic approach where the vehicle’s foundation is designed exclusively for electrification. A primary driver of this evolution is the transition toward high-voltage architectures. By adopting systems that operate at significantly higher voltages—such as 800V—engineers can drastically improve energy transfer efficiency. This shift allows for the use of thinner, lighter cabling to transmit power, reducing overall vehicle weight while simultaneously enabling faster charging times and more potent motor output.

Parallel to this electrical evolution is a physical transformation of the vehicle's skeleton. Modern manufacturing is increasingly utilizing large-scale casting technologies, where massive sections of the chassis are formed as single, continuous pieces rather than dozens of welded parts. When combined with advanced structural adhesives and lightweight aluminum alloys, this approach enhances rigidity while shedding unnecessary mass. This is not merely about making the car lighter; it is about optimizing the entire energy flow. By integrating the battery pack directly into this unified structure, manufacturers can eliminate redundant bracing. The result is a platform where every millimeter is optimized, allowing for a lower center of gravity that mimics a sports car, yet retains the comfort and range of a grand tourer. This architectural purity eliminates wasted space, providing designers with the freedom to reimagine the vehicle not just as a machine, but as a seamless conduit for energy and motion.

| Feature | Traditional Retrofit Platform | Next-Gen Dedicated EV Architecture |

|---|---|---|

| Space Utilization | Constrained by transmission tunnels and engine bays | Flat floor design maximizes interior volume and storage |

| Energy Efficiency | Higher weight due to redundant structural bracing | Optimized weight via integrated casting and structural batteries |

| Thermal Management | Complex routing of cooling systems around ICE legacy parts | Centralized thermal systems managing battery and cabin simultaneously |

| Design Flexibility | Limited by fixed hard points of internal combustion engines | High modularity allowing varied body types on a single base |

The Virtual Proving Ground and Material Evolution

Digital Twins and the Quest for Sustainable Manufacturing

Long before a physical bolt is tightened, the next generation of vehicles exists entirely in the digital realm. The design process has shifted from physical prototyping to sophisticated virtualization, often referred to as "digital twins." In this highly detailed virtual space, engineers can replicate the entire vehicle ecosystem, subjecting it to millions of simulated miles and varied environmental conditions. This computational power allows for the precise prediction of complex behaviors, such as how a motor's temperature fluctuates under heavy load or how the battery's thermal management system responds to extreme weather. By solving these thermodynamic puzzles in the digital phase, development timelines are compressed, and the substantial waste associated with building and scrapping physical test mules is eliminated.

This digital foresight extends beyond performance; it deeply influences cost efficiency and environmental sustainability. By analyzing successful designs and simulating manufacturing processes, automakers can select component configurations that offer the best balance of performance and cost. Furthermore, the environmental footprint of the manufacturing process itself—energy consumption and emissions—is calculated and minimized during the design phase. This seamless integration of simulation and reality ensures that when production finally begins, the vehicles are not only high-performing but are also produced with a level of precision and economic efficiency that was previously unattainable. It paves the way for high-quality, sustainable mobility to become accessible to a broader demographic.

The Solid-State Revolution and Chemical Breakthroughs

While the structural architecture provides the bones, the chemistry within the battery cells provides the lifeblood. The industry is currently on the cusp of a major transition from liquid electrolyte lithium-ion batteries to all-solid-state batteries. This chemical evolution addresses the two most critical concerns for drivers: range anxiety and safety. By replacing the flammable liquid electrolyte with a solid conductive material, the risk of thermal incidents is drastically reduced. This inherent safety allows engineers to simplify the heavy protective casings and complex cooling systems required by current batteries, further reducing weight and freeing up space.

More importantly, solid-state technology unlocks a new tier of energy density. It allows for a greater amount of energy to be stored in the same physical footprint, potentially doubling the range of vehicles compared to today’s standards. This breakthrough implies that future electric vehicles could cover distances comparable to internal combustion engines on a single charge, effectively removing the psychological barrier of long-distance travel. Additionally, future platforms are being designed with "energy agnosticism" in mind. They are engineered to be modular enough to accept not just solid-state batteries, but potentially hydrogen fuel cells or other emerging energy carriers. This flexibility ensures that the platform remains relevant regardless of which energy technology becomes dominant, securing a sustainable path toward zero emissions.

Harmonizing Safety with Dynamic Freedom

Turning Structural Weight into Protective Strength

The placement of the battery pack—often the heaviest component in an electric vehicle—fundamentally changes the safety dynamics of the car. By arranging the battery cells in a flat, wide formation across the bottom of the chassis, engineers create an exceptionally low center of gravity. This physical characteristic inherently resists rollover forces, providing a level of stability that taller, engine-heavy vehicles struggle to match. However, this design does more than just keep the car planted on the road; the battery enclosure itself has evolved into a critical safety member.

Modern designs utilize the battery case as a structural "spine" that enhances the vehicle's torsional rigidity. Constructed from ultra-high-tensile steel or specialized aluminum alloys, this reinforced housing serves as a formidable shield. In the event of a side impact, the battery frame works in concert with the door sills and pillars to act as a barrier, absorbing immense pressure. Furthermore, the absence of a large, solid engine block in the front allows for the creation of superior "crumple zones." Without a massive metal object threatening to intrude into the passenger cabin during a frontal collision, the front structure can be optimized to collapse progressively. This design employs a "multi-load path" strategy, dispersing the crash energy like water flowing around a rock—diverting forces through the roof rails, side sills, and floor, away from the occupants and the high-voltage system.

| Safety Aspect | Function in Modern EV Architecture | Benefit to Occupants |

|---|---|---|

| Rollover Resistance | Heavy battery pack placed at the lowest point of the chassis | drastically reduces the likelihood of overturning during sharp maneuvers |

| Frontal Impact | Utilization of the empty front trunk (frunk) space | Acts as a superior shock absorber, dissipating energy before it reaches the cabin |

| Side Impact | Reinforced battery housing integrated into the frame | Provides a rigid wall of protection that prevents cabin intrusion |

| Force Distribution | Multi-load path structural design | Channels crash energy around the passenger cell rather than through it |

Unlocking Spatial Potential through Component Flexibility

The liberation from the mechanical constraints of the internal combustion engine—specifically the driveshaft, exhaust system, and transmission tunnel—has ushered in a golden age of interior design and dynamic control. The compact nature of electric motors allows them to be positioned directly on the axles or even within the wheels. This placement facilitates a completely flat floor, transforming the cabin from a cramped cockpit into a spacious lounge. Designers can now implement sliding consoles, swiveling seats, and open layouts that were physically impossible in previous automotive eras.

This layout flexibility extends to the vehicle's movement dynamics. With motors independently controlling the front and rear axles—or even individual wheels—the vehicle can execute maneuvers that defy conventional physics. Advanced torque vectoring allows for instant adjustments to traction, providing enhanced stability in hazardous conditions. In more extreme applications, independent wheel control enables "crab walking," where the vehicle moves diagonally, or allows it to spin in place. This level of granular control means that the platform can morph to suit the driver's needs, offering the agility of a sports car in the canyons and the maneuverability of a compact pod in tight urban parking spaces. The modular nature of these subframe units means a single platform can support a sedan, an SUV, or a utility vehicle, all sharing the same intelligent DNA.

Q&A

-

What is the significance of skateboard platform integration in modern vehicle design?

Skateboard platform integration is crucial in modern vehicle design as it allows for a flexible and scalable architecture. This approach centralizes components like the battery, motors, and control systems into a flat, unified base. This not only simplifies manufacturing but also enables automakers to design various body styles on the same platform, reducing costs and time to market.

-

How does centralized power distribution enhance vehicle performance?

Centralized power distribution enhances vehicle performance by ensuring efficient energy management throughout the vehicle. By centralizing the electrical components, it reduces the complexity of wiring, minimizes energy losses, and improves the overall reliability of the vehicle's electrical system. This setup is particularly beneficial for electric vehicles, where energy efficiency is paramount.

-

What are modular subframe units and their advantages in automotive engineering?

Modular subframe units are pre-assembled sections of a vehicle's frame that can be easily integrated into the overall structure. These units provide several advantages, including easier assembly, improved structural integrity, and the ability to customize or upgrade specific sections of the vehicle without redesigning the entire frame. This modularity supports rapid prototyping and production flexibility.

-

How does a structural battery chassis contribute to vehicle design?

A structural battery chassis integrates the battery pack into the vehicle's frame, contributing to both energy storage and structural support. This dual-purpose design reduces weight and increases rigidity, enhancing vehicle safety and performance. By using the battery pack as a load-bearing element, manufacturers can optimize space and improve the vehicle's overall efficiency.

-

What role does motor placement optimization play in vehicle dynamics?

Motor placement optimization is critical in determining the vehicle's handling, stability, and efficiency. By strategically placing motors, engineers can achieve optimal weight distribution and center of gravity, which enhances traction and control. This optimization is particularly important in electric vehicles, where the absence of a traditional engine allows for more flexible motor placement options.

-

How is crash energy dispersion integrated into vehicle safety design?

Crash energy dispersion is a key aspect of vehicle safety design, involving the strategic distribution of impact forces throughout the vehicle's structure. This technique minimizes the force experienced by occupants during a collision, reducing the risk of injury. By integrating materials and design elements that absorb and channel energy away from the passenger compartment, automakers can enhance the protective capabilities of their vehicles.