The Science of Efficiency: Redefining Warmth

Harvesting Energy for a Smarter Cabin

The transition from internal combustion engines to electric powertrains has fundamentally altered the physics of keeping a car warm. In traditional vehicles, heat was an abundant waste product of the engine, readily available to be blown into the cabin. In an electric vehicle (EV), however, heat is a precious commodity that must be generated using battery power, which creates a direct conflict between passenger comfort and driving range. This dilemma has birthed a sophisticated approach to thermal management that treats heat not as a byproduct, but as a valuable asset to be harvested, moved, and conserved.

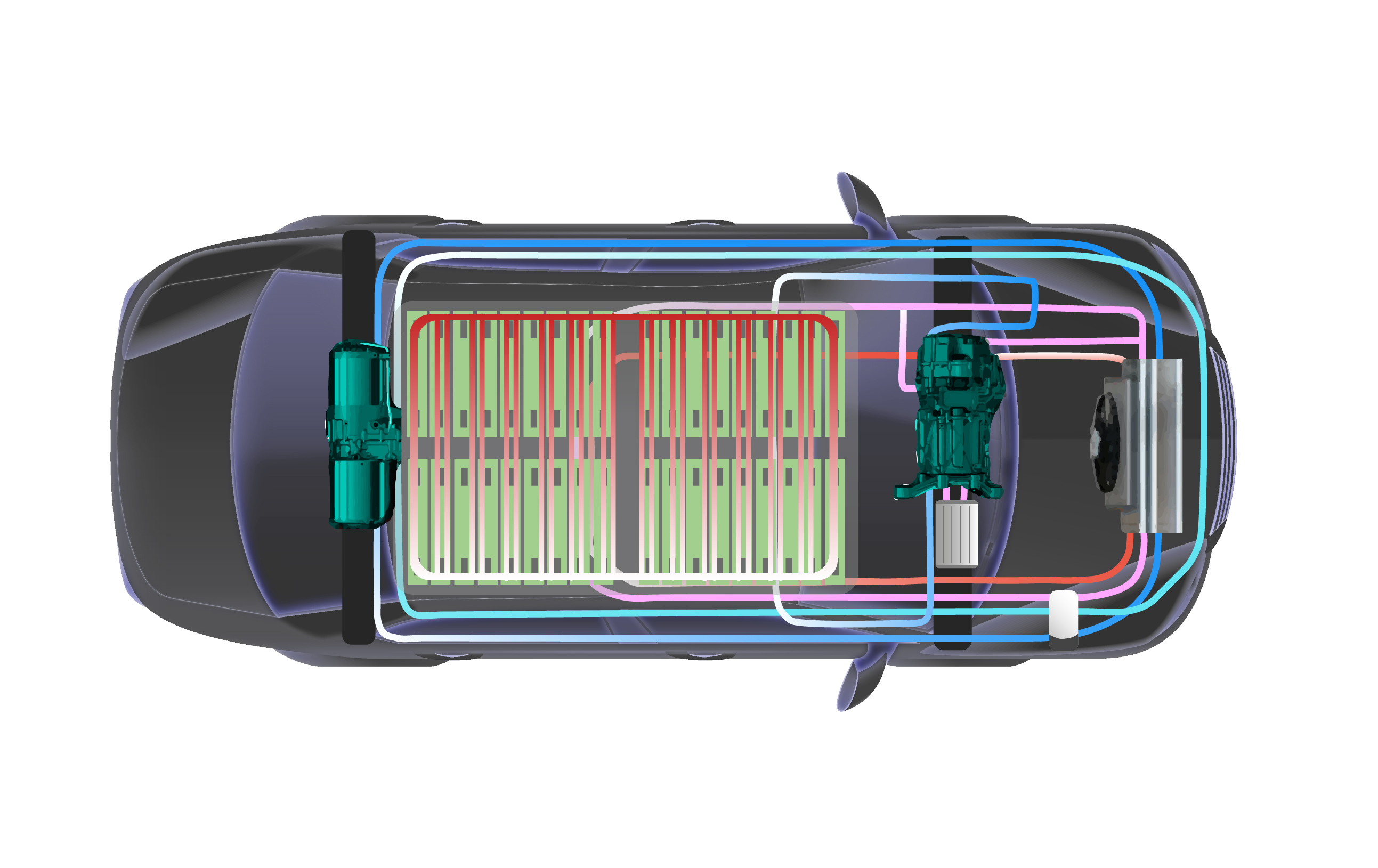

Modern thermal systems operate like a complex thermal bank. They scavenge waste heat from the electric motor, the inverter, and even the battery pack itself. Instead of letting this energy dissipate into the atmosphere, advanced heat pump technologies compress and redirect it to warm the cabin. This process is significantly more efficient than traditional resistive heating, which works like a giant toaster wire and consumes vast amounts of electricity. The engineering challenge lies in the delicate balancing act: the system must keep the battery within its optimal operating window—neither too hot nor too cold—while simultaneously answering the occupants' demand for a cozy environment.

This integration goes beyond simple mechanics; it involves predictive software that analyzes external weather conditions and driving patterns. If the navigation system knows the car is approaching a fast charger, the thermal management system will pre-condition the battery to the perfect temperature for rapid charging, while managing the cabin temperature to ensure the driver remains unaware of the redirection of thermal resources. This holistic view of energy consumption transforms the climate control system from a simple accessory into a core component of the vehicle’s powertrain efficiency strategy.

Precision Comfort: The Rise of Microclimates

Targeting the Passenger, Not the Space

A paradigm shift is occurring in how automotive engineers approach interior comfort: moving away from heating the volume of air to heating the occupants directly. Heating the entire cabin air mass is energetically expensive and slow. By focusing on the immediate space surrounding each passenger, a concept often referred to as "zonal comfort," manufacturers can achieve higher satisfaction levels with a fraction of the energy consumption. This approach acknowledges that human thermal comfort is largely determined by the temperature of surfaces we touch and the airflow immediately around our faces and bodies.

The evolution of seat technology plays a pivotal role here. Modern seats are no longer just static cushions with a simple heating wire; they are becoming active thermal management devices. Advanced systems can ventilate moisture away from the body in summer while delivering rapid, targeted warmth in winter. Beyond the seats, we are seeing the integration of radiant heating panels in door trims, armrests, and even the steering column. These surfaces emit heat that warms the passengers directly through radiation, similar to how the sun warms the skin on a cold day, without needing to overheat the surrounding air.

This granular control extends to airflow as well. Instead of blasting air from a central dashboard, smart vents can direct gentle breezes exactly where needed, avoiding the drying effect of strong air currents on the eyes while maintaining freshness. By creating these individual comfort bubbles, the vehicle can reduce the workload on the main HVAC compressor. The result is a dramatic reduction in energy draw, which translates directly to extended driving range, particularly in harsh winter conditions where range anxiety is most prevalent.

| Feature | Traditional Cabin Heating | Zonal Microclimate Control |

|---|---|---|

| Primary Target | Entire volume of cabin air | Occupant bodies and contact surfaces |

| Energy Consumption | High (requires constant heating of circulating air) | Low to Medium (direct transfer is more efficient) |

| Response Time | Slow (air takes time to warm up) | Fast (radiant/contact heat is felt instantly) |

| Comfort Perception | Can feel stuffy or dry | Feels natural, similar to sitting by a fireplace |

| Impact on Range | Significant reduction in cold weather | Minimal impact due to targeted efficiency |

Material Innovation and Sensory Experience

The Invisible Engineering Behind Weight and Insulation

While screens and software get the headlines, a silent revolution is happening within the structural materials of electric vehicles that directly impacts climate control. To maximize the efficiency of thermal systems, engineers are ruthlessly eliminating weight and improving insulation. Every kilogram saved in the vehicle structure is a kilogram that the motor doesn't have to haul, leaving more energy available for the climate control systems. This has led to the replacement of traditional metal components in the thermal loop—such as valves, pipes, and connectors—with advanced composites and multi-layer resin structures.

These new materials offer a dual benefit: they are significantly lighter than their aluminum or steel predecessors, and they possess superior thermal insulation properties. In a traditional metal setup, valuable heat is lost as it travels through pipes from the heat pump to the cabin. High-tech polymers, however, act as insulators, ensuring that the thermal energy generated or harvested reaches its destination with minimal loss. Furthermore, the battery pack itself is often wrapped in specialized elastomeric foams that protect it from extreme external temperature fluctuations, reducing the energy needed to keep the pack at its happy operating temperature.

The reduction of weight also creates a virtuous cycle. A lighter vehicle requires less energy to move, which reduces the thermal load on the battery and motor, which in turn reduces the cooling requirements. This intricate dance of material science allows for smaller, more compact thermal management units, freeing up cabin space for passengers. It is a classic example of "less is more," where invisible material upgrades provide tangible benefits in range and seasonal reliability.

Silence and Air Quality: The Sanctuary Effect

The electric powertrain has removed the masking noise of the internal combustion engine, revealing a new challenge: silence. In a gas car, the rumble of the engine hides the sound of the wind, the tires, and the whirring of the air conditioning fan. In an EV, the cabin is a library-quiet environment where the sound of air rushing through vents can become intrusive. Consequently, the acoustic engineering of climate control has become a priority. Engineers are redesigning ductwork and vents to smooth out airflow, eliminating turbulence that causes hissing or whooshing sounds.

Simultaneously, the concept of the vehicle as a "third living space" has elevated the importance of air quality. Modern consumers expect their vehicle to offer a sanctuary from the pollution of the outside world. This has led to the standardization of hospital-grade filtration systems capable of stripping out ultrafine particles, allergens, and even viruses before they enter the cabin. These systems often work in tandem with sensors that monitor exterior air quality; if the car detects high pollution levels in a tunnel or city traffic, it automatically seals the cabin and recirculates internal air through high-efficiency filters.

This focus on a pristine, quiet environment transforms the drive. It is no longer just about temperature; it is about the holistic sensory experience. The combination of thermal comfort, acoustic isolation, and purified air reduces cognitive load and fatigue for the driver. It turns the daily commute into a restorative experience, leveraging the inherent advantages of the electric platform to offer a level of serenity that was previously the domain of ultra-luxury limousines.

| Component | Function in Thermal Comfort | Benefit to Passenger Experience |

|---|---|---|

| Acoustic Glass | Insulates against noise and temperature | Creates a quiet, stable interior environment |

| Composite Ducting | Reduces weight and thermal loss | Improves range and system responsiveness |

| HEPA Filtration | Removes microsized particles | Ensures health and reduces allergy symptoms |

| Silent Air Vents | Diffuses air without turbulence noise | Maintains the "library-quiet" EV atmosphere |

| Insulated Battery Housing | Maintains optimal battery temp | Prevents range loss in extreme weather |

Q&A

-

What are Localized Peltier Zones and how do they work in vehicle climate control systems?

Localized Peltier Zones refer to specific areas within a vehicle's interior where Peltier elements are used to provide precise temperature control. Peltier elements, also known as thermoelectric coolers, can both heat and cool by creating a temperature differential when an electric current passes through them. In vehicle climate control systems, these zones allow for tailored thermal environments, enabling passengers to adjust the temperature of their immediate surroundings without affecting the entire cabin.

-

How does Infrared Cabin Heating differ from traditional heating systems in vehicles?

Infrared Cabin Heating uses infrared radiation to directly heat objects and passengers in the vehicle, rather than warming the air like conventional systems. This method is more energy-efficient as it reduces the time and energy needed to achieve a comfortable temperature. It is particularly beneficial in cold climates, providing immediate warmth to passengers and surfaces upon entry.

-

What is Adaptive Vent Flow and how does it enhance passenger comfort?

Adaptive Vent Flow is a feature in modern climate control systems that adjusts the direction and intensity of air vents based on passenger preferences and environmental conditions. This technology uses sensors to detect factors like body temperature, sunlight exposure, and cabin occupancy. By dynamically adapting the airflow, it enhances passenger comfort and optimizes energy usage by directing air only where needed.

-

How does Heat Pump Optimization contribute to vehicle efficiency and comfort?

Heat Pump Optimization in vehicles involves using a heat pump system to transfer heat between the interior and exterior of the vehicle efficiently. This technology can both heat and cool the cabin, depending on the needs. By optimizing the operation of the heat pump, vehicles can achieve better energy efficiency, especially in electric vehicles, where conserving battery power is crucial. Additionally, it provides a more consistent cabin climate, enhancing overall passenger comfort.

-

What role does Thermal Energy Recovery play in modern automotive climate systems?

Thermal Energy Recovery is a process where waste heat from the engine or other components is captured and reused within the vehicle, often to assist in heating the cabin or pre-warming other systems. This not only improves the overall energy efficiency of the vehicle by reducing the need for additional fuel or power to heat the cabin, but it also contributes to faster warm-up times and reduced emissions, aligning with the goals of sustainable automotive design.